![[Translate to English:] Sägen [Translate to English:] Zuschneiden mit Kreissäge](/fileadmin/user_upload/bbcgroup.biz/site/plastictech/images/used/003-Services/0034/003-ServicesZuschnittPlatten6.1_1400x450-min.jpg)

Pre-cut plastic

Your partner for custom-made plastic panels, rods and pipes for individual processing.

Pre-cut plastics for needs-based quantities and accurate dimensions

To be machined on a milling or turning machine, the semi-finished product must be pre-cut at an angle and according to specific dimensions. Our pre-production facilities are equipped with a range of machines for the following processes:

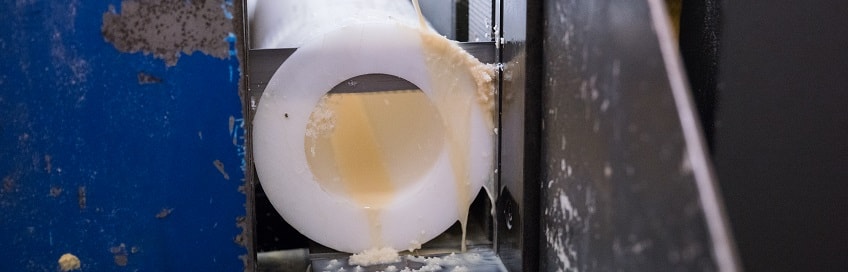

- Centreless grinding of rods and pipes

- Sawing of panels, rods and pipes

- Planing and chamfering of panels and profiles

Ground rods for further processing on type turning machines

- Ground to a nominal diameter or customer-specific diameters

- Ground diameter from Ø 1.8 to 50 mm

- Tolerance according to ISO tolerance series IT 8 – 11 (depending on the material)

- Defined surface quality

- Rod length up to 3,000 mm

- Sharpened, chamfered or turned finish for ends

![[Translate to English:] Centerless Schleifen [Translate to English:] Schleifen, Kunststoff Rundstäbe](/fileadmin/user_upload/bbcgroup.biz/site/plastictech/images/used/003-Services/0034/003-ServicesCenterlessSchleifen1_848x272-min.jpg)

Pre-cut panels

Our panel saws can process panels up to 3,000 x 3,800. Depending on the material, we can cut thicknesses from 1 to 130 mm.

Depending on the panel thickness and size of the part, we can achieve the following tolerances:

- Cutting in tolerance range +/- 0.5 mm

- Precision processing +/- 0.1 mm

- Precision sawing +/-0.2 mm

- Precision planing +/- 0.1 mm

Our planing machines can process thicknesses from 5 – 300 mm and widths up to 610 mm.

Planing the panel thickness can have benefits for further processing:

- Increased angle accuracy

- Defined surface quality

- Low-tension components (less deformation, better accuracy)

![[Translate to English:] Herstellung von Plattenzuschnitten [Translate to English:] Kunststoffplatten zuschneiden](/fileadmin/user_upload/bbcgroup.biz/site/plastictech/images/used/003-Services/0034/003-ServicesZuschnittPlatten1_848x272-min.jpg)